Description

Key benefits:

- Exceptional colour consistency

- Improved product performance

Colorants – Paste or Liquid Pigment Dispersion

Epoxy

Wall & Floor Coating, Anti-Corrosive Coatings, Other Specialist Coating

PVC-Flexible

Vinyl Wrapping & Graphic Films, Coated Fabrics, Safety Flooring, Safety Wear, Conveyor Belting

Polyurethane

Cast and Injection Moulded Components, Playground and Sports Surfaces, Flooring and Roofing, Military Camouflage, Tools and Mould Making, Safety Wear, Pipeline Coatings

Polyester Composites

General Moulding, Architectural Moulding, Automotive Parts, Poles and Masts, Caravans and Motorhomes, Boats and Marine, Roofing, Machine Housings, Truck and Bus Fittings, Pultrusion, Kerb Edges, Drainage Systems, Sports Equipment

Colorants – Powder

Epoxy

Decorative & Industrial Flooring Screeds, Aggregate & Cementitious Blends used in Construction Applications

PVC-Rigid

Extruded Profiling – Typically Windows & Doors, Pipes & Fittings and Internal & External Cladding etc, Extruded Sheeting – Typically Roofing, Cladding & Signage etc.

Polyurethane

Polyester Composites

Polyester Compound

Compression Moulded Polyester Compounds (SMC / DMC / BMC)

Rubber Systems

Flooring & Underlay, Conveyor Belting

Thermoplastic Roadmarking

Additives – Paset or Liquid Additive Dispersions

Epoxy

Wall & Floor Coatings: low-odour, water-borne industrial floor coatings; coatings for bitumen, asphalt and concrete, hygiene coatings, chemically-resistant wall coatings. In liquid or paste form based on Phthalate or Non-Phthalate Plasticisers suitable for Flexible PVC products. Anti-Corrosive Coatings.

PVC- Rigid & Flexible

Conveyor Belting, Curtain Sides & Tarpaulin, Graphic Films / Decals, Medical Dressing & Prosthetics, Safety Flooring, Safety Wear

Polyurethane

Medical Dressings & Prosthetics

Polyester Composite

Drainage Systems, Kerb Edges, Automotive Parts, Boats & Marine, Caravans & Motorhomes, Equipment & Machine Housings, Roofing, General & Architectural Mouldings, Mezzanine Flooring, Poles & Masts, Safety Rails & Ladders, Signs, Sports Equipment, Truck Bodies

Chemical Foaming Agents

Fascom™ Chemical Foaming Agents are a range of polymer additives of significant technical importance for providing production, economic, environmental and physical improvements when processing a wide range of polymers. WSL have been developing and marketing this advanced technology since the 1980’s. Demand is increasing as many firms embrace this new technology within an evolving application portfolio, and the advantages it can offer.CFA’s are different than other classes of polymer additive – they are designed to decompose during normal processing of that polymer at elevated temperatures (150ºC+). On doing so, they release a high volume of gas which can be trapped within the polymer melt creating a cellular or foamed structure. By forming a cellular structure the initial benefit created is a reduction in specific gravity i.e. Weight. This reduction affords a number of potential properties including :-• Easier Handling (reduced transport costs, ease of installation)• Reduced Polymer Requirement (less polymer = lower cost, environmental gain, reduced taxation)• Improved Product Dimensions (anti sink performance in moulding, increased volume without the weight, increased thickness = increased rigidity)• Improved Insulation (sound, thermal)• Cushioning (shock absorption)• Design Aesthetics (surface detailing, three dimensional patterns)• Aquatic (the product may float)The choice of CFA is important as many options exist. WSL have an extensive range of products and chemistries designed to cover numerous applications, process methods and temperatures. Typical applications for liquid dispersed foaming agents include;PVC plastisols for flooring, wallcovering, belting and artificial leather. Other applications may also exist where companies wish to take advantage of the dust free handling a liquid dispersion allows. We offer technology developed to a final application and our dedicated technical service allows customer bespoke products for optimised performance. Whether it is production handling, dosing, base formulation, mixing or end use (technical/foaming requirements) that is your critical need. With dedicated manufacturing capacity as part of our production facility, we have a range of liquid pre-dispersions and are able to supply formulated technologies across a broard range of concentrations and viscosity.

Additives – Powder

PVC – Rigid

PVC – Flexible

Chemical Foaming Agents

Fascom™ Chemical Foaming Agents are a range of polymer additives of significant technical importance for providing production, economic, environmental and physical improvements when processing a wide range of polymers. WSL have been developing and marketing this advanced technology since the 1980’s. Demand is increasing as many firms embrace this new technology within an evolving application portfolio, and the advantages it can offer.CFA’s are different than other classes of polymer additive – they are designed to decompose during normal processing of that polymer at elevated temperatures (150ºC+). On doing so, they release a high volume of gas which can be trapped within the polymer melt creating a cellular or foamed structure. By forming a cellular structure the initial benefit created is a reduction in specific gravity i.e. Weight. This reduction affords a number of potential properties including :-• Easier Handling (reduced transport costs, ease of installation)• Reduced Polymer Requirement (less polymer = lower cost, environmental gain, reduced taxation)• Improved Product Dimensions (anti sink performance in moulding, increased volume without the weight, increased thickness = increased rigidity)• Improved Insulation (sound, thermal)• Cushioning (shock absorption)• Design Aesthetics (surface detailing, three dimensional patterns)• Aquatic (the product may float)The choice of CFA is important as many options exist. WSL have an extensive range of products and chemistries designed to cover numerous applications, process methods and temperatures. Typical applications include; uPVC foamed profile, pipe and sheet, PVC plastisols for flooring, wallcovering, belting and artificial leather, Polyolefines for extrusion, injection moulding and rotational moulding and Rubber for extrusion and moulding operations. We offer technology developed to a final application and our dedicated technical service allows customer bespoke developments for optimised performance with regard to your production handling, dosing, base formulation, mixing and final end use technical/foaming requirements.

With a dedicated manufacturing site as part of our production facility, we have a range of blending and dispersion options allowing supply in raw component form, pre-blended modified technologies, liquid pre-dispersions and pre-weighed dust free sachets (FASPAK). Our new 2 ton plough share blender has recently been added to our production unit and has achieved a tremendous improvement in both efficiency and quality control.

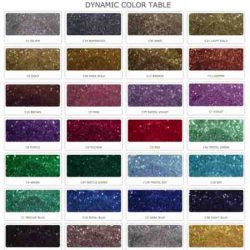

Fastint – Mono Pigment Range

This range is for Gelcoat / Resin Manufacturers & Distributors wishing to pigment their products quickly and efficiently; it is available for Polyester, Epoxy, PU & PVC systems. An economical way of making almost any shade including RAL, BS and other established colour ranges using 20 stock tinters. A faster way of manufacturing products for your customer, with minimal investment. Fastint™ will reduce your stock inventory. Scalable solutions available ranging from manual tinting through to a fully automated production facility. Our iMatch online colour matching service can be used in conjunction with our Fastint™ Multi Polymer Mono-Pigment Range.